Shot blasting of steel - what is shot blasting of metal?

Metal surface treatment is often used to improve appearance, durability, corrosion protection or to prepare the surface for further processes such as painting, galvanizing or gluing. One of the methods of surface treatment of metals is shot blasting. What is worth knowing about this process? We explain!

What is metal shot blasting?

Metal shot blasting is the process of mechanically removing material from a metal surface using a stream of grains, called shot. Shot blasting can be done manually or with machines. This process is designed to improve the appearance and quality of the metal surface by removing contaminants, oxidation, rust, paint or other coatings, and smoothing out unevenness.

Steel shot blasting basics

When blasting steel, a stream of grains (usually made of metal, such as steel, stainless steel, aluminum, etc.) is directed towards the surface to be cleaned. The shot grains hit the surface at high speed, which removes impurities and gives a uniform appearance. This process can be controlled in terms of grain impact force, jet velocity and the type of shot used for shot blasting.

Abrasive blasting - what is it and how does it work?

Abrasive blasting is the process of mechanically removing material from a surface using a stream of abrasive grains such as sand, steel balls, glass beads or ceramics. It is a method used to clean, smooth, remove impurities, improve the appearance of the surface or change its properties. Examples of blasting methods include shot blasting and sandblasting.

During abrasive blasting, the abrasive is directed in the form of a strong stream onto the surface of the workpiece. This is done through special devices - such as ejectors or sandblasting devices, which generate high grain velocity.

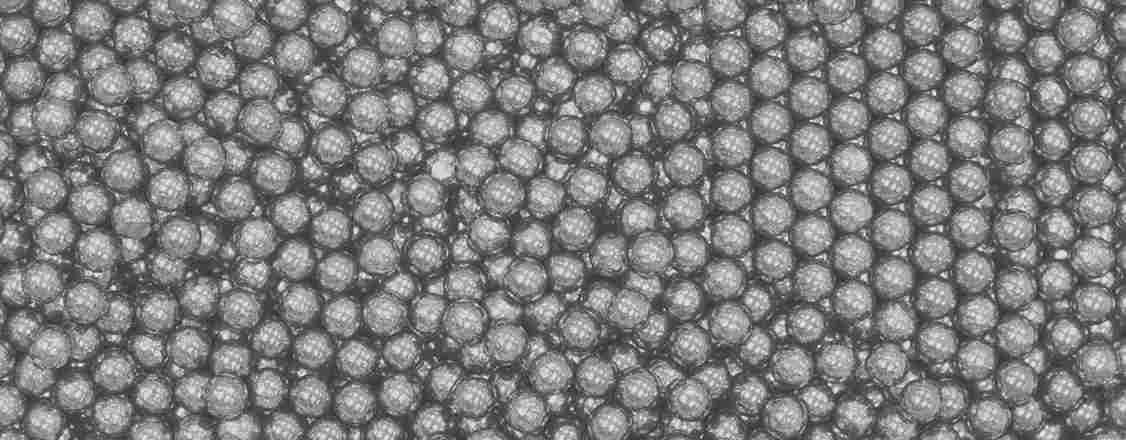

Steel shot - the key to effective shot blasting

Steel shot are small balls made of steel that are used in various fields, mainly in the metal industry, in the metalworking process. Steel shot is produced by casting or cutting steel wire into small pieces, which are then shot peened and quenched to the proper hardness and strength. These balls come in a variety of sizes depending on the application and can be spherical, cylindrical or conical.

Cast steel shot has many advantages, including durability, corrosion resistance and reusability. However, care should be taken when handling this material as it can be hazardous when in contact with the human body. Therefore, the use of appropriate personal protective equipment, such as safety glasses and gloves, is extremely important when carrying out the blasting process.

Key benefits and applications of steel shot blasting

The shot blasting process brings many benefits, such as cleaning the surface of impurities, rust and paint, and removing the corrosion layer. Through this process, clean and prepared surfaces are obtained, which are ready for further processing, painting, galvanizing or applying other protective coatings.

Steel blasting has many uses. It can be used, for example, in the automotive industry for surface preparation prior to painting or varnishing, in the shipbuilding industry for cleaning and preparing ship hulls, in the aerospace industry for paint stripping and surface preparation prior to repair or painting, and, for example, in the defense industry for restoring worn parts to working condition.

WAbrasives - experts in steel shot blasting

If you are looking for cast steel shot, tooling, or expert advice related to the topic of metalworking - it is worth visiting the WAbrasives store. Here you will receive the support of experts helping in the development of your business in the metallurgical industry. We provide assistance in the selection of pellets and specialized equipment in accordance with the profile of your business.