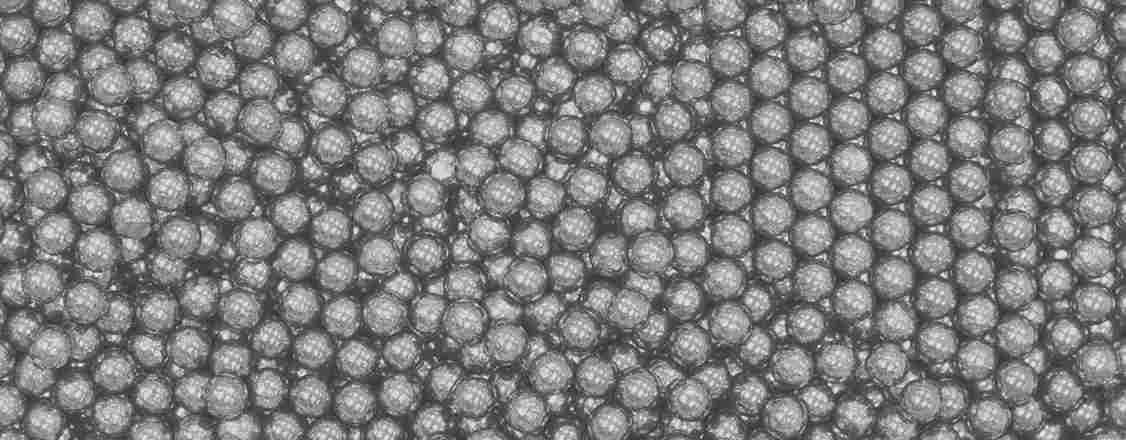

Ścierniwa ze stali nierdzewnej: skład, właściwości i zastosowania

Ścierniwa ze stali nierdzewnej wyróżniają się wyjątkową trwałością, odpornością na korozję i wysoką efektywnością pracy. Kluczowymi pierwiastkami w ich składzie są chrom i nikiel — to właśnie one w największym stopniu wpływają na parametry robocze i żywotność tych materiałów.

W poniższym opracowaniu wyjaśniamy, jak skład ścierniw nierdzewnych przekłada się na ich właściwości, jakie ich rodzaje stosuje się w przemyśle oraz w jakich procesach zapewniają one największe korzyści.

Rola chromu i niklu w ścierniwach nierdzewnych

Stal nierdzewna wykorzystywana do produkcji ścierniw zawiera przede wszystkim chrom i nikiel.

- Chrom odpowiada za odporność na korozję — tworzy na powierzchni warstwę pasywną, która chroni ścierniwo i obrabiany materiał przed utlenianiem.

- Nikiel zwiększa udarność i wytrzymałość ścierniwa, co pozwala mu pracować pod dużymi obciążeniami bez ryzyka kruszenia.

Synergia tych pierwiastków sprawia, że ścierniwa nierdzewne są nie tylko trwałe, ale też minimalizują ryzyko zanieczyszczenia powierzchni żelazem. To kluczowe w branżach wymagających wyjątkowo czystej, odpornej na korozję powierzchni — m.in. spożywczej, medycznej czy przy obróbce aluminium.

Ścierniwa ze stali nierdzewnej są przeznaczone do obróbki materiałów, gdzie wymagana jest eliminacja ryzyka kontaminacji żelazem, takich jak: stal nierdzewna, aluminium, tytan, brąz i stopy kolorowe.

Rodzaje ścierniw ze stali nierdzewnej

Stelux C

- Skład: ok. 16% Cr, 0,5–1,5% Ni

- Zastosowania: czyszczenie i przygotowanie powierzchni do dalszych procesów (malowanie, trawienie chemiczne)

- Branże: motoryzacja, odlewnie

- Cechy: zachowanie integralności powierzchni, delikatny profil